Capabilities and Applications

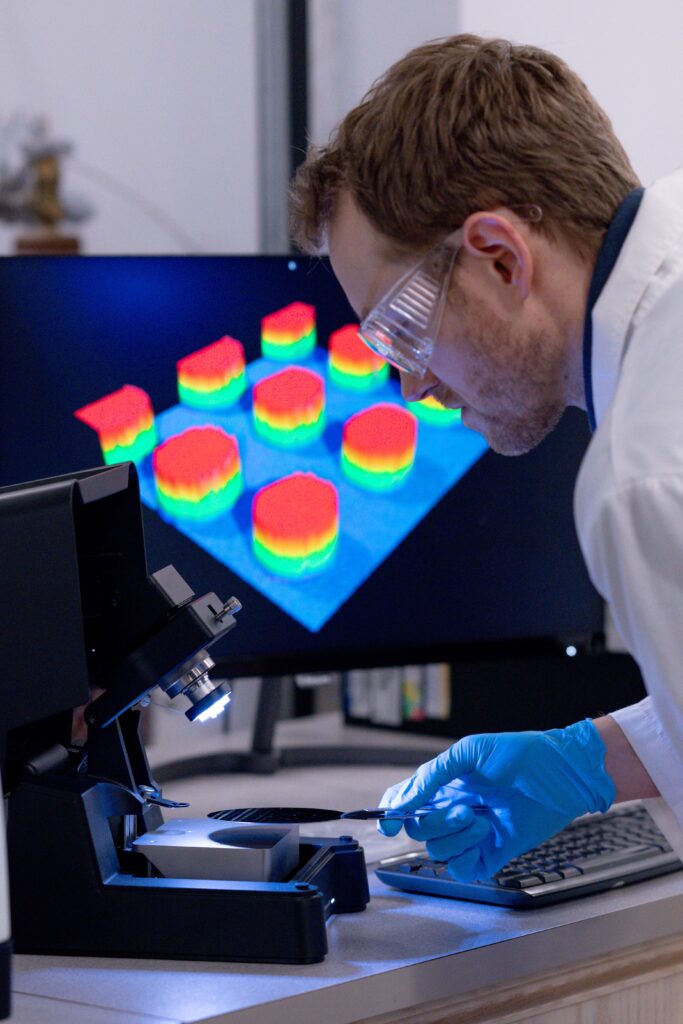

Capabilities

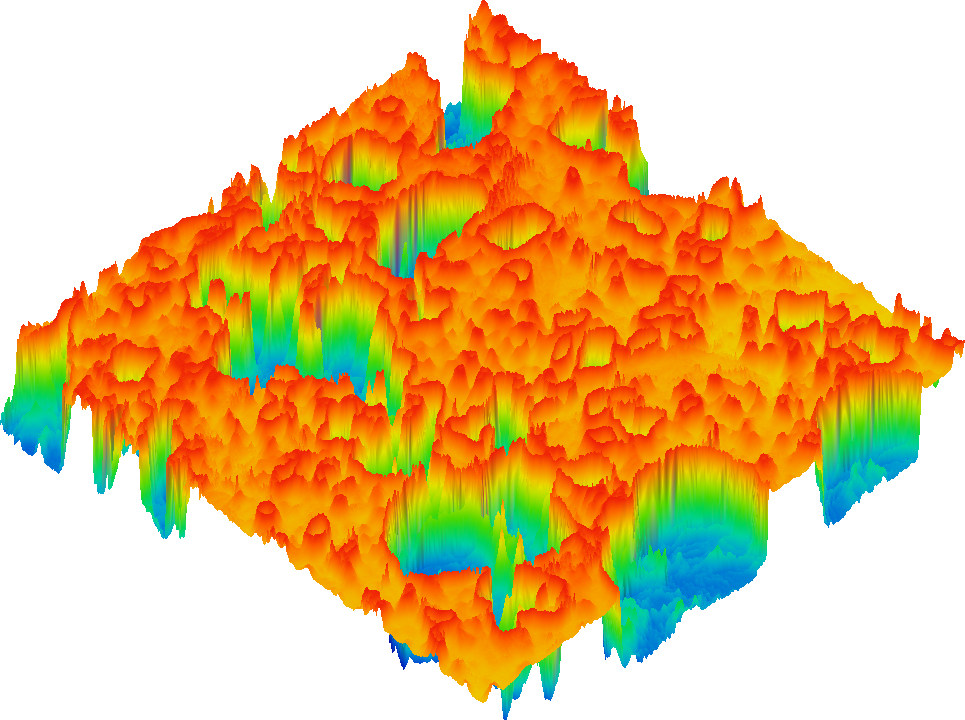

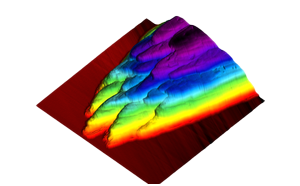

Roughness

Go beyond line profiles and Ra: get high-resolution quantitative data across the surface.

Applications

Polymers and Composites

Collect nanoscale topography data of polymers, co-polymers and composites with extremely high spatial resolution.

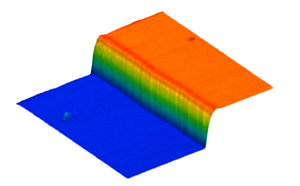

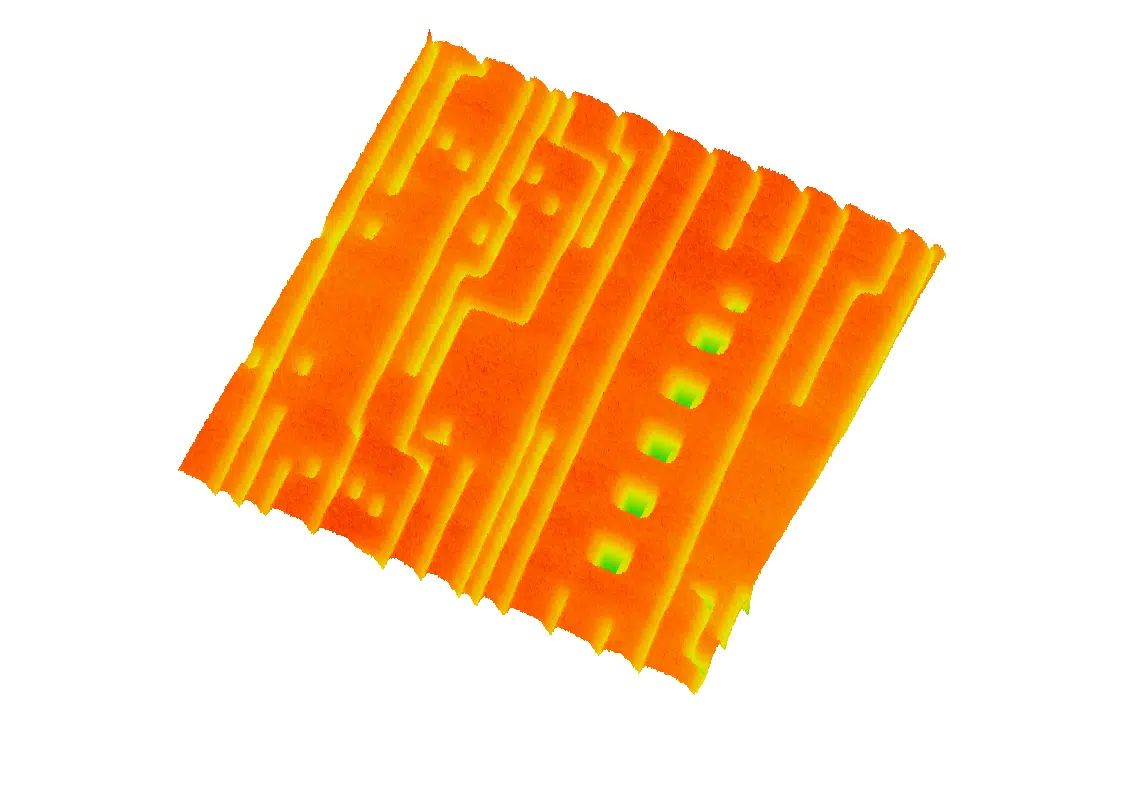

Microfabrication

Thin-film, critical dimension and structure characterization in 3D at the nanoscale.

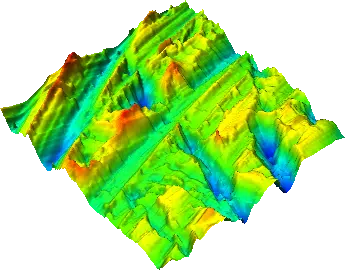

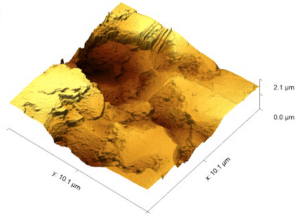

Metals and Minerals

Determine surface finish, investigate morphology and characterize grain structure.

Ceramics

Quickly measure grain size and surface morphology for ceramics in sintering processes and more, with extremely high resolution.

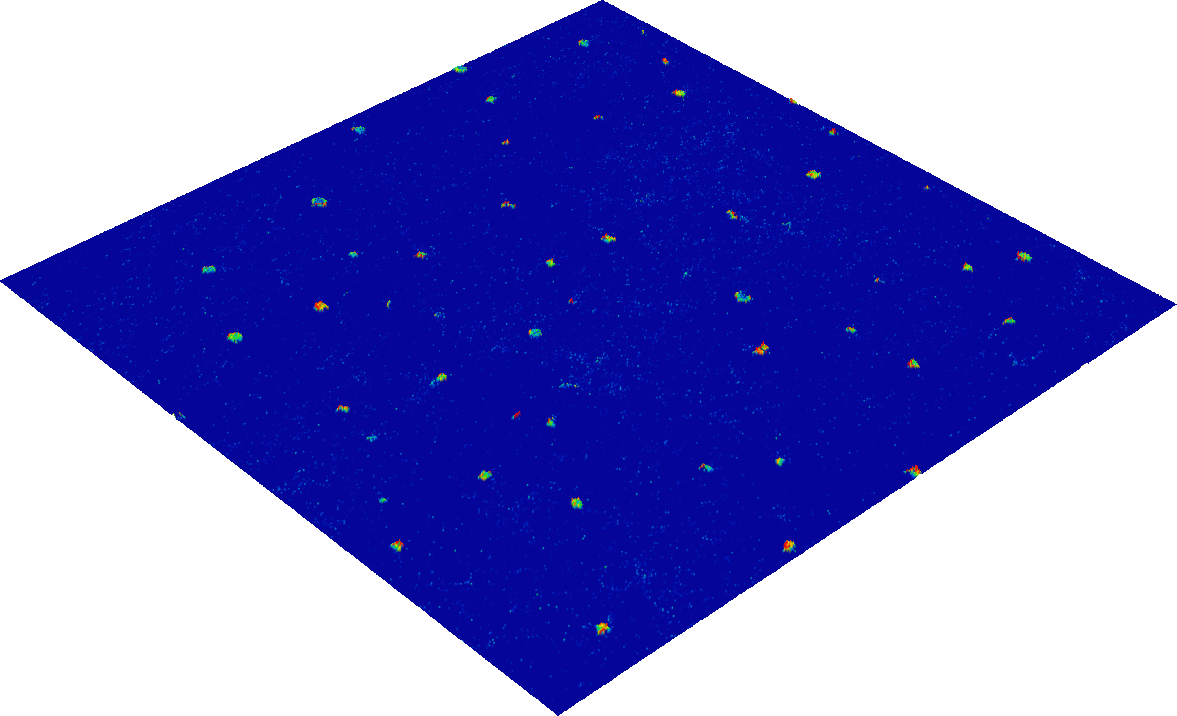

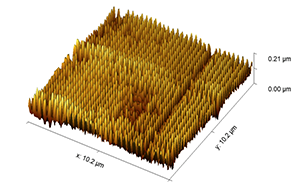

Nanoimprint Lithography

Inspect molds and patterned substrates and verify critical dimensions and roughness.

Biology and Life Science

Gain insights into the structure of biological materials with minimal sample preparation.