Redux AFM

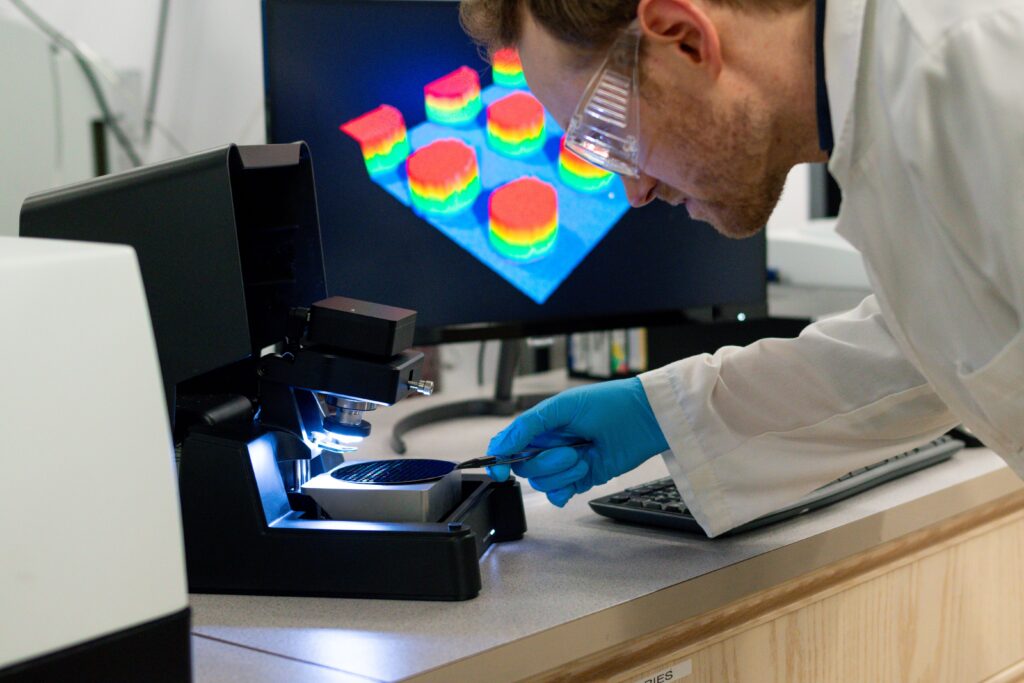

Effortlessly collect 3D topography data with sub-nanometer precision on your benchtop with the Redux AFM. The Redux offers unmatched time-to-results, ease of use and hassle-free operation.

See the nanoscale in 3D with the Redux AFM

Go beyond other techniques and collect high-resolution, quantitative data on your benchtop in minutes.

Precise

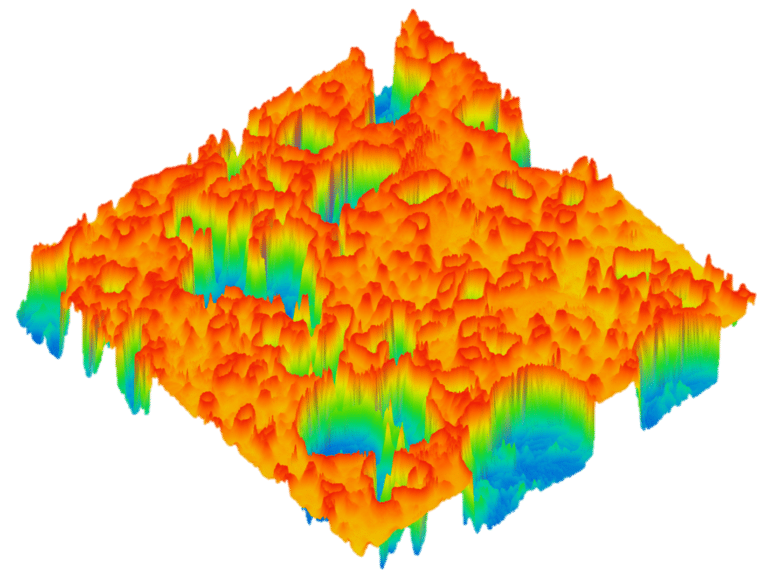

Quantitative 3D data with sub-nanometer precision

Automated

Motorized X, Y and Z stages for easy sample navigation

Fast

Go from sample loading to data in minutes

Versatile

Topography, roughness, thickness, particle size and more

Watch the full demo video of the Redux AFM

Unmatched time-to-results and ease of use: go from loading a sample to data in minutes

One instrument. Many solutions.

Make better decisions with quantitative 3D nanoscale data on your benchtop.

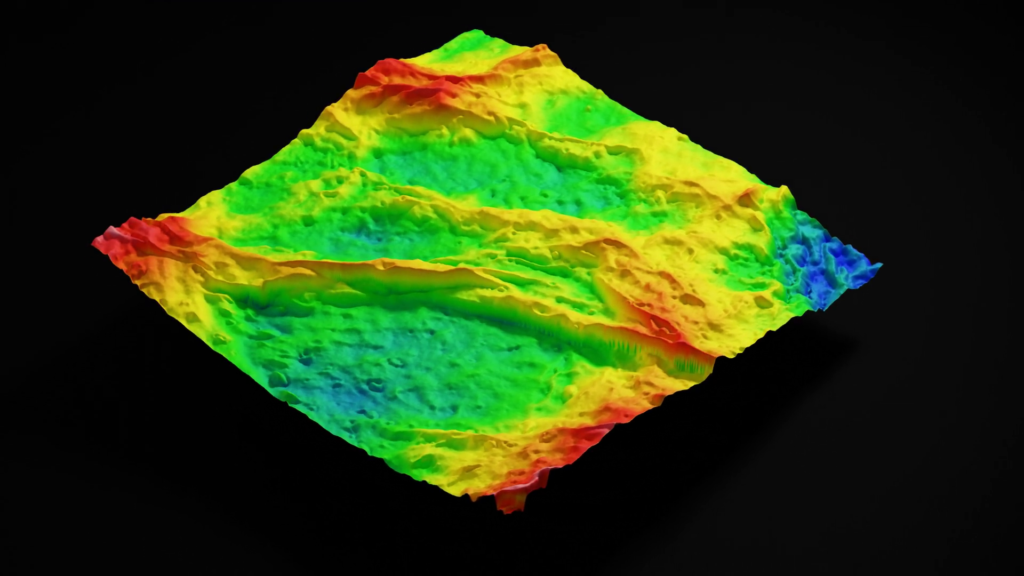

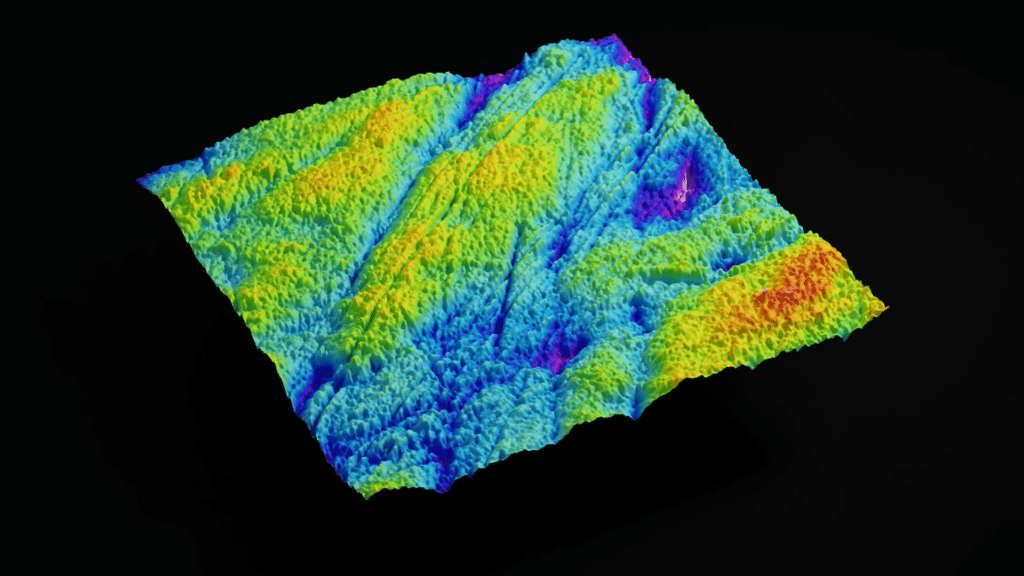

Get insights at the nanoscale with quantitative high-resolution topography data.

Go beyond line profiles and Ra: get high-resolution quantitative data in 3D.

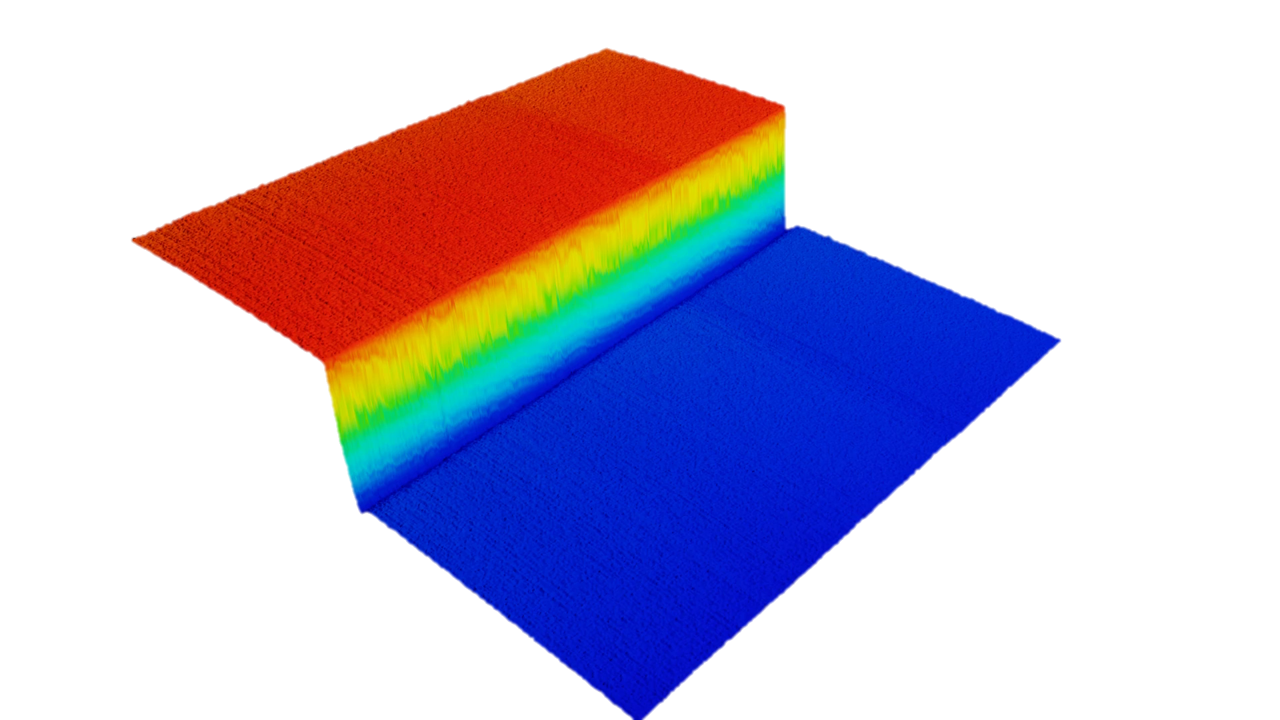

Measure dimensions, including film thickness and step heights accurately.

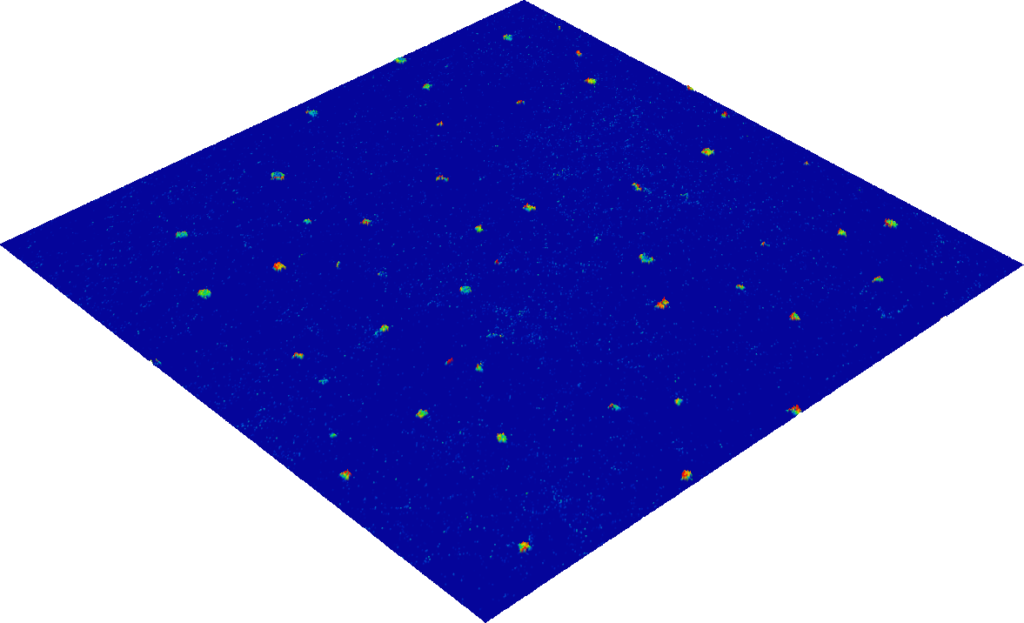

Determine particle size, shape and distribution with sub-nanometer resolution.

Discover the spatial distribution of components with different properties.

Effortless

- One-click configuration

- One-click automatic approach in seconds

- Laser alignment-free operation

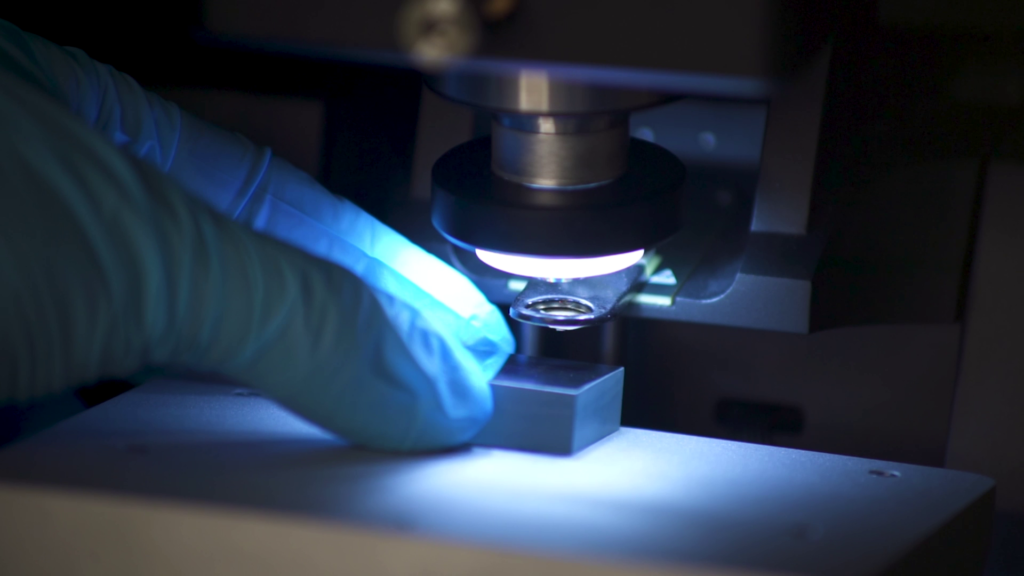

Unlike traditional AFMs, the Redux has no laser alignment step or manual approach: an integrated sensor on the AFM chip automates everything for you.

Compatible with your sample

- Opaque or transparent, conductive or non-conductive samples

- Minimal to no sample preparation and non-destructive scanning

- Generous sample platform (125 mm x 100 mm / 5" x 4")

The Redux is compatible with virtually any solid sample, including adhesive samples.

Ultra-durable probes

- Extremely low tapping force

- Easy handling

- Integrated sensor prevents tip crashes

Our unique AFM chips have durable probes that last hundreds of scans without noticeable wear. The AFM chips are mounted onto easy-to-handle printed circuit boards (PCBs) that can even be handled by hand.

Specifications

| AFM Specifications | |

| Sensing | Self-sensing, laser alignment-free |

| Z actuation | Self-actuating |

| XY actuation | Electrothermal |

| Max scan area (XY) | 20 μm x 20 μm |

| Z Range | 20 μm |

| Scan speed | 80 seconds (256 x 256 pixel, 20 μm x 20 μm) |

| Noise floor | <0.5 nm rms |

| XY Scanner resolution | <0.5 nm |

| Samples | |

| Sample platform size | 125 mm x 100 mm |

| Max sample height | 20 mm |

| Max sample weight | 250 g |

| Sample condition | Dry |

| Motorized XY Stage | |

| Sample positioning range (XY) | 12 mm x 12 mm |

| Integrated Optical Microscope | |

| Objective | 10x, 0.25 NA |

| Field of view | 1.4 mm × 0.8 mm |

| Resolution | 1920 x 1080 FHD video output |

| Sample illumination | Integrated LED lighting |

| System Dimensions | |

| Dimensions (L x W x H) | 23.2 cm × 22.0 cm × 24.6 cm |

| Weight | 4 kg |

| Software and I/O | |

| Communication | USB |

| Operating System | Windows 10, 11 |

| Data output | Raw (tsv) Processed (png) Gwyddion / AFM analysis software (gsf) |

| Power | |

| Power supply | Class II (two prong) |

| Input | 100-240 VAC ~ 50/60 Hz |

| Output | 12 VDC, 3 A |

| What's in the box | |

| System | Redux AFM system, including optical microscope, motorized XY stage and environmental cover 2x USB-C to USB-A cables Power supply Ground cable (banana plug to alligator clip) AFM chips Tweezers Spare thumb nut |

| Accessories | Acoustic enclosure Vibration isolation table |

| Optional accessories | Calibration gratings Laptop (pre-loaded with operating and analysis software) |

Frequently Asked Questions

Both the Redux and nGauge systems use our AFM-on-a-chip technology to make nanoscale imaging effortless.

The Redux has a higher level of automation, combining an integrated optical microscope and motorized XY stage controls, and it also has a sample platform that can accommodate larger samples.

Compare the specs here!

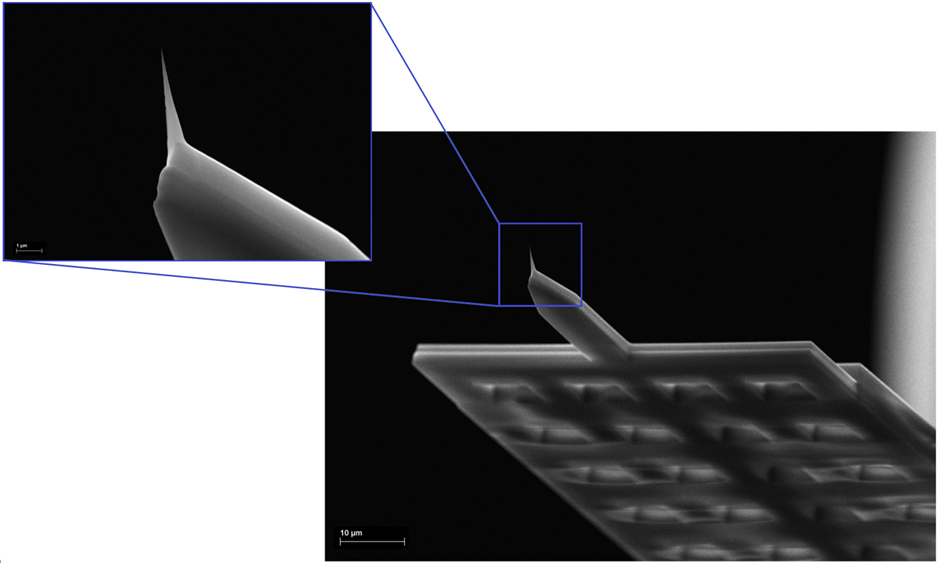

Our AFM chips are made with state-of-the-art microelectromechanical systems-based (MEMS) technology that make our systems fast, easy-to-use and work like magic. Each chip features an integrated, laser alignment-free sensor, precise XYZ scanners, and cantilever with tip for imaging.

You can read more about the chips on our page!

The Redux is so fast because many of the requirements for legacy AFM are streamlined away with many sensors and scanners being integrated on the chip itself. This allows for steps like the tip-to-sample approach to be automated. Combined with the motorized sample stage, much of the overhead of legacy AFM is removed and you can get great scans in minutes!

Nope! With our AFM-on-a-chip technology, the legacy AFM requirement of time-consuming laser alignment is done away with.

Yes! Our AFM-on-a-chip technology is interchangeable between our products.

For most samples, yes! There is very little sample preparation required for most samples. Transparent or opaque, conductive or non-conductive, adhesive or not, they can all be scanned. Scanning curved samples is no issue as well since any curvature usually does not show up on the micron length scale.

It’s important that the sample does not move during scanning. For lightweight samples like foils, paper, and for flexible or round samples that could roll (wire, hair), we recommend affixing them to a substrate (glass slide, mica disc) or a simple jig.

Yes! Refer to the question above this one.

Generally yes! The reason is that even if the morphology across the sample shows high variation, within the lateral scan area it will typically never reach those levels.

The Redux sample stage is motorized in X, Y and Z, and controlled through the operating software.

Each AFM chip lasts more than 50x the lifetime of traditional AFM probes and can be used for thousands of scans.

Check out this time lapse video of scans taken using our technology as a showcase.

We strongly recommend using a vibration isolation table to reduce noise and get optimal results. We offer passive and active vibration isolation tables, specifically selected for the Redux.

We strongly recommend using an acoustic enclosure to reduce environmental noise for optimal performance. We offer an acoustic enclosure designed for the Redux.

The Redux does not currently support scanning liquid samples.

Yes! Please refer to our Roughness capabilities page for more information.

The Redux operates in intermittent contact mode and collects topography and phase images.

The Redux does not currently provide force-distance curves.

Yes! Refer to our product specifications for sizing.

The Redux does not currently support in-vacuum operation and is meant for operation in ambient conditions.