AFM Chips

Our AFM chips are powerful, durable and easy-to-use.

ICSPI's AFM-on-a-chip Technology

Redefining ease-of-use

Our AFM chips are made with state-of-the-art microelectronics technology called micro-electro-mechanical systems (MEMS) that make our AFM systems fast, easy-to-use and work like magic.

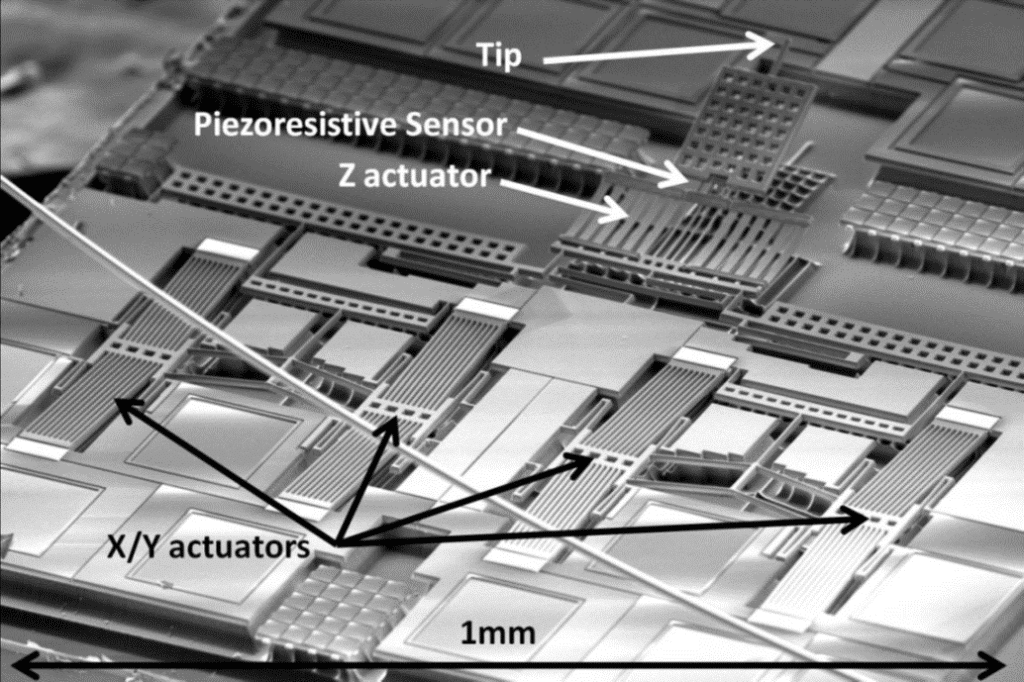

Many of the bulky components that make traditional AFM systems so complicated have been miniaturized onto a single 1 mm2 chip.

Each chip features an integrated, laser alignment-free sensor, precise XYZ scanners, and cantilever with tip for imaging.

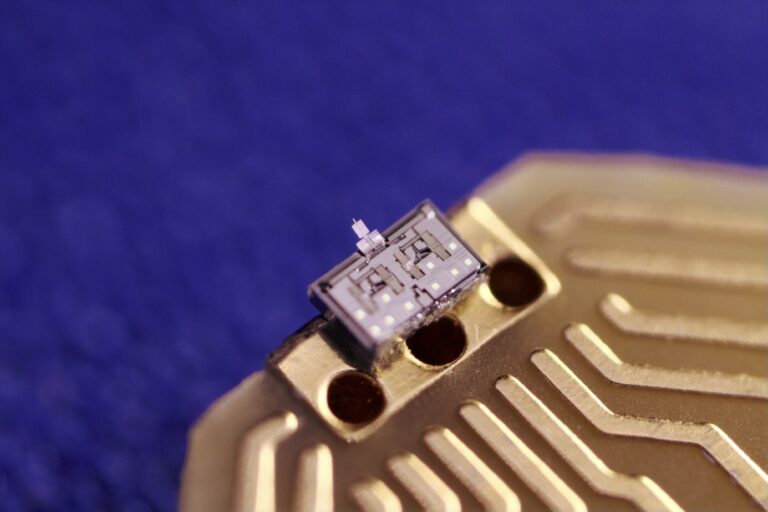

Easy to handle

Each AFM device is mounted on the end of an easy-to-handle carrier. Unlike traditional AFM systems, our chips are easy to handle and can even be handled by hand.

Laser alignment-free

Our AFM chips have built-in sensors for detecting the forces between the tip and sample. Traditional AFM systems use a laser-based detection system that requires multiple, time-consuming manual steps to align. Traditional AFM systems also require a manual approach from the tip to the sample, meaning you have to watch and stay focused on the screen during the entire approach.

Because of the built-in sensor, our systems are laser alignment-free and the approach is completely automated, so you can focus on your research and quality control — not on instrument set-up.

Durable

The tip on our AFM chips lasts much longer than typical AFM tips (which may last only 20-50 scans). As the tip interacts with the sample, the tip will get blunter and blunter, so features normally appear dilated after scanning.

The unique architecture of our AFM chips and the very low stiffness of the cantilever (0.1 N/m) enables a very low interaction force between the tip and the sample and an extremely long lifetime of over 1000 scans without noticeable wear.

Tip Specifications

Two different types of tips are available depending on resolution requirements: diamond-like carbon (DLC) tips for high-resolution and general-purpose imaging, and alumina wedge (WDG) tips for coarse imaging, training and step height measurements.

Diamond-like Carbon (DLC)

Our DLC tips are recommended for all applications. DLC tips are particularly useful for measuring fine structures (<100 nm in size laterally). Examples include:

- Small biological structures

- Nanoparticles

- Membranes

- Roughness (fine)

Wedge (WDG)

Recommended for imaging larger structures and step heights, where high lateral resolution isn’t a concern. Examples include:

- Step heights

- Particles (> 500 nm)

- Roughness (coarse, >1 um)

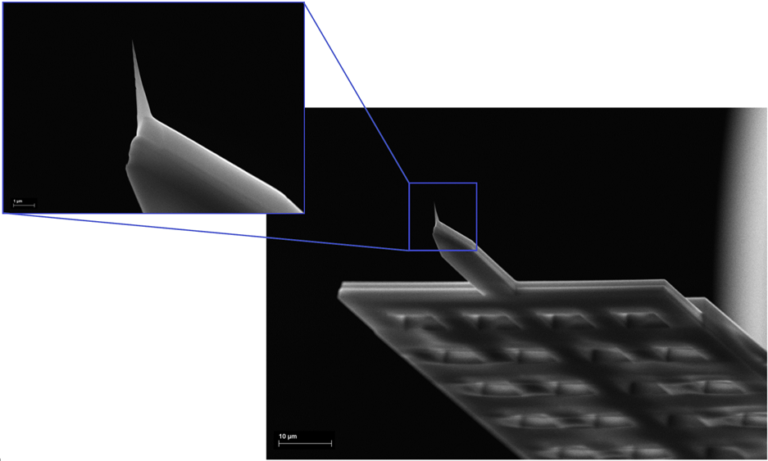

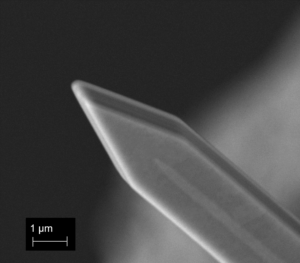

High-Aspect Ratio Diamond-Like Carbon (DLC) Tips

Ideal for general imaging and for demanding applications.

Our DLC tips offer excellent lateral resolution with a tip radius of <20 nm. DLC is a durable material that enables hundreds or thousands of scans without noticeable degradation in scan quality.

Our DLC tips are tilt-compensated by 15º to provide symmetrical, high-fidelity scans. The DLC tip is >1 µm tall.

DLC is a low surface energy material, meaning that it also offers excellent contamination resistance (against particles, debris, polymer build-up and other contaminants).

Tip radius

Tip height

Cone angle

Aspect ratio

Tilt compensation

Tip shape

Tip material

<20 nm

>1 µm

<10º

>3

15º

Conical

Diamond-like carbon

Aluminum Wedge (WDG) Tips

Ideal for coarse imaging, training and step heights.

Alumina is a durable material that enables hundreds or thousands of scans without noticeable degradation in scan quality.

The native oxide (alumina) of aluminum is a low surface energy material, meaning that it also offers excellent contamination resistance (against particles, debris, polymer build-up and other contaminants).

Tip radius (effective)

Tip shape

Tip material

<150 nm

Wedge

Alumina

Cantilever

The tip of the AFM is located at the very end of the cantilever beam. The cantilever on our chips have the same specifications.

Cantilever Specifications

Shape

Resonant frequency

Stiffness

Beam

8 kHz (typical: 7 – 9 kHz)

0.1 N/m

Length

Width

Thickness

30 µm

6 µm

3 µm