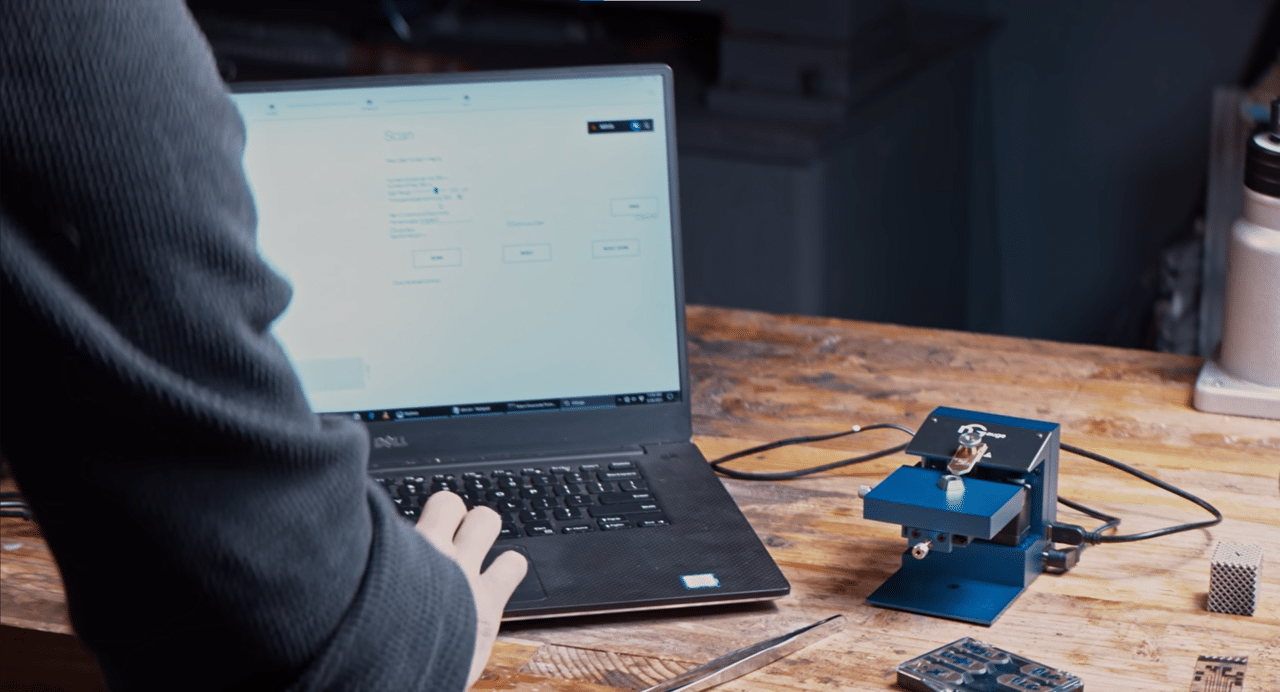

Introducing the Redux AFM

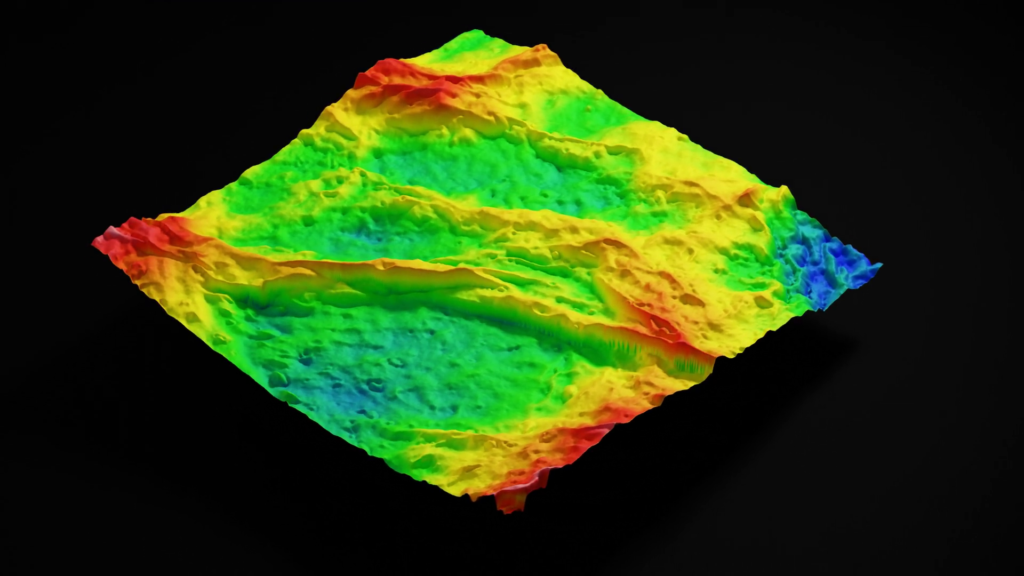

Effortlessly collect images with sub-nanometer precision on your desktop with the Redux atomic force microscope. The Redux has a motorized XY stage and offers unmatched time-to-results, ease of use and hassle-free operation.

Effortless nanoscale imaging

Powerful

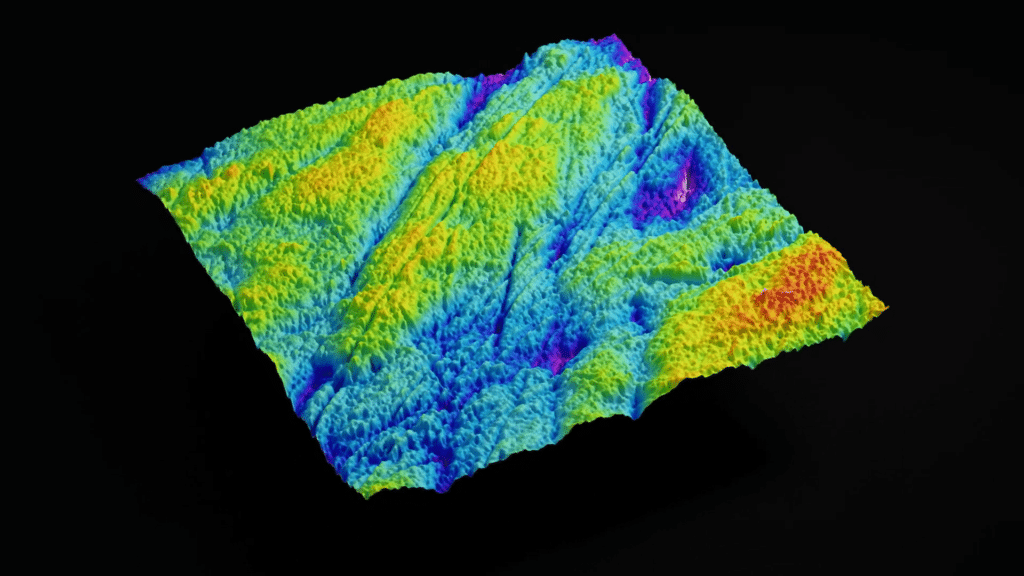

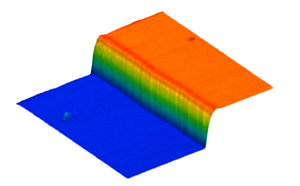

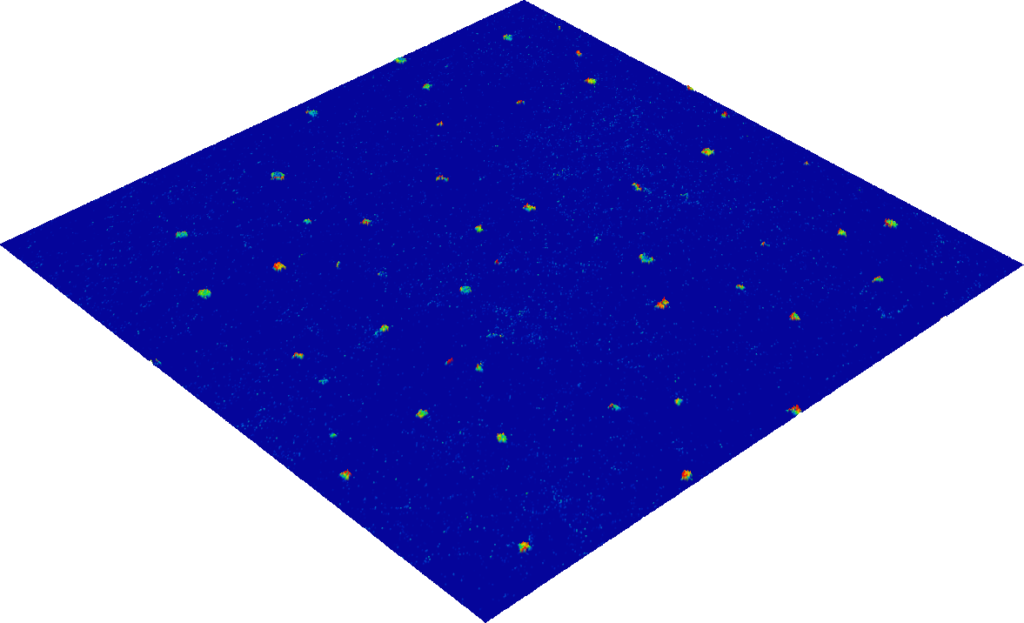

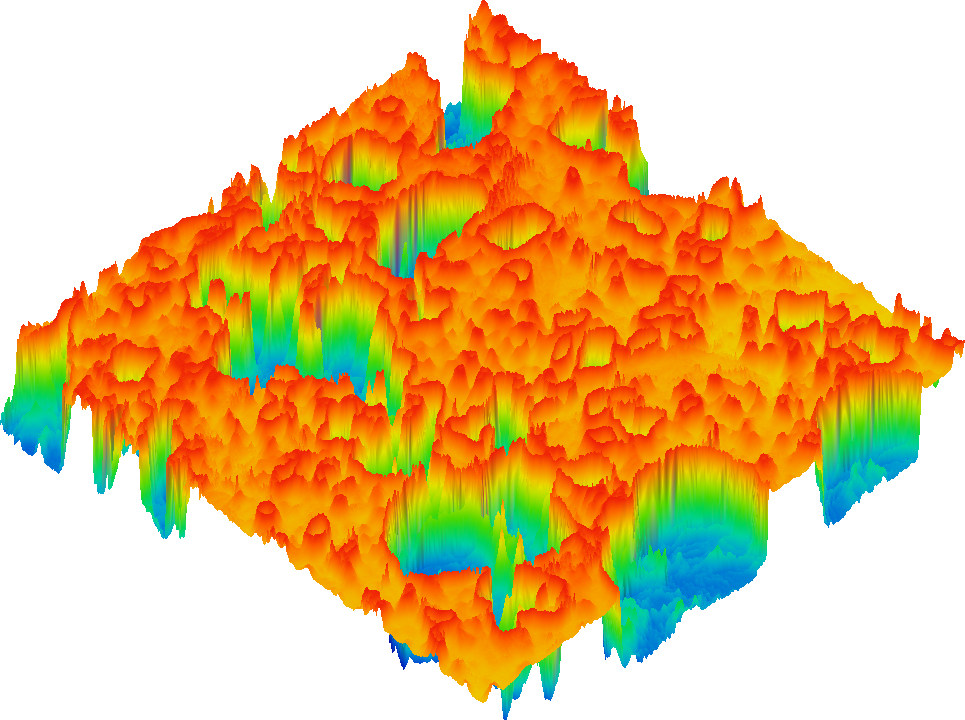

Quantitative 3D data with sub-nanometer precision

Fast

Go from sample loading to data in minutes

Automated

One-click configuration and no laser alignment

Versatile

Topography, roughness, thickness, particle size and more

One technique. Many solutions.

Make better decisions — faster — with quantitative 3D nanoscale data.

Effortless nanoscale imaging on any benchtop

See how the nGauge AFM is used to make nanoscale discoveries

on the material science channel Breaking Taps

on the material science channel Breaking Taps

Trusted by scientists, engineers and educators worldwide

"We have been blown away by the nGauge AFM’s performance, ease-of-use and portability. The tool easily saves us several thousand dollars a month."

"This technology is extremely reliable and can provide images that rival much larger, traditional AFM systems."

"The nGauge allows us to accurately measure the thickness of our nanoscale diffractive optics. We have increased our yield and it has helped characterize our devices."

"I get numerical data instead of just an idea based on the picture using optical microscopy. That is really helpful for us in formulating our suspensions."

"The nGauge distinguishes itself from other options in the AFM market through its simplicity in both tool setup and operation. This ease of use proves particularly valuable for core facilities with diverse users and applications, facilitating quick training and efficient tool utilization."

University of Alberta nanoFAB

"...the nGauge makes AFM much easier, more convenient and opens a lot of doors for us, especially as an AFM expert for biological samples and surface characterisation. This has given me a great way to share and communicate my findings much more clearly with collaborators and to quickly test samples at different laboratories and sites, making collaboration between institutes much easier."

"The AFM proved to be highly useful for glovebox usage where our polymer electrolyte (unstable in air, hygroscopic) was able to be characterized quickly. We were able to confirm the roughness of the polymer surface without subjecting it to SEM's harsh vacuum, which might introduce artifacts. It is a pleasure using this machine."

Who uses our instruments?