AFM for Metals and Minerals

Common applications of AFM for metal and minerals

Atomic Force Microscopy (AFM) can serve as a highly effective tool for chracterizing metals and minerals at the micro- and nanoscales, catering to diverse applications in automotive, aerospace, and electronics industries. Serving as a complementary technique to conventional metallurgical microscopy, AFM offers detailed inspection of structural and material properties.

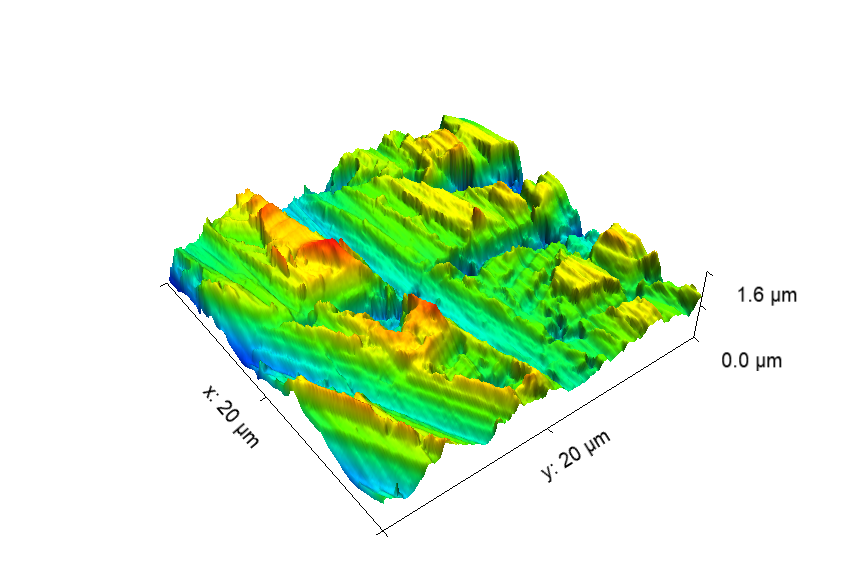

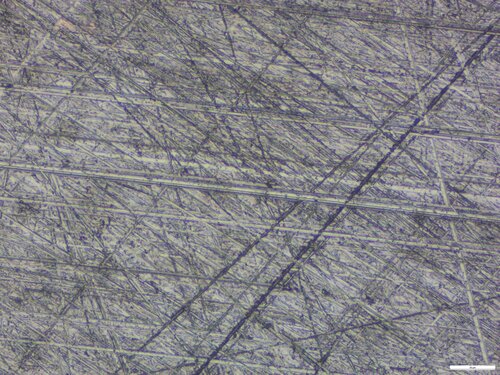

Illustrated through the inspection of a steel sample polished with polycrystalline diamond suspension, the limitations of optical microscopy become apparent, as it provides minimal quantitative data, especially regarding scratch depth and width. In contrast, our AFMs offer significantly higher resolution, enabling precise measurement of features such as scratch width and depth.

With its exceptional resolution, AFM surpasses optical microscopy by providing three-dimensional data, facilitating quantitative measurements of surface features. For instance, the density of scratches on a polished surface can be accurately calculated, speeding up process development and quality control protocols.

Akasel A/S

Speak with an expert

Interested to learn more about how AFM can help you characterize your metal samples?