AFM for Polymers and Composites

AFM Topography Imaging for Polymers and Composites

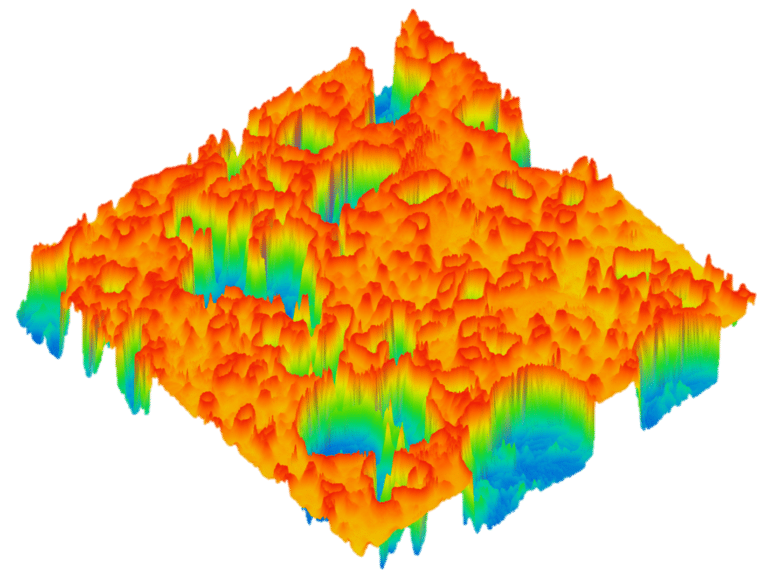

Atomic Force Microscopy (AFM) is a versatile technique for characterizing and analyzing polymers and composites. AFM collects high-resolution 3D images of the surface, and can even collect data for samples that can be tricky to image with optical or electron microscopy, such as non-conductive or transparent samples.

The 3D images can be used to characterize morphology, and because the images themselves are quantitative, topographic data like the surface roughness can be determined. If there is a step height (like an interface where the film is coated, or a scratch), the film thickness can also be accurately measured with AFM.

Spatial distribution of components in polymers and composites

The most common mode of operation for AFM is tapping mode, where the AFM stylus (also known as the tip) is driven to oscillate above the surface of the sample. AFM tip-sample interaction induces a phase shift in the feedback signal, revealing qualitative mechanical information about the surface. This data, visualized as a phase image, sheds light on adhesive, frictional, and viscoelastic forces experienced by the tip. Topography and phase images are acquired simultaneously when operating in tapping mode.

The distinction between topographical and phase data is stark when examining samples composed of different materials. For example, composites like a silica-polymer composite, or even copolymers like ABS, show large contrasts in the phase image. This means that the spatial distribution of components in a sample can be determined with <10 nm precision, all using a non-destructive technique that does not require sample preparation.

ICSPI's AFM systems for polymer and composite characterization

ICSPI’s AFM systems like the nGauge AFM and Redux AFM are ideal for quickly and accurately characterizing polymer and composite samples, whether they are coatings, films, workpieces or adhesives. In particular, the Redux AFM is equipped with a motorized XY positioning stage, so navigating to a region of interest (like a scratch, or landing onto a thin wire) is hands-off.

Speak with an expert

Interested to learn more about how AFM can provide insight on your polymer and composite samples?