Blog

How Akasel A/S uses the nGauge AFM for metal polishing process control

ICSPI makes the nGauge Atomic Force Microscope (AFM) — a benchtop scientific instrument that makes it easy to get nanoscale topography data and reveal important insights.

Akasel A/S is a manufacturer of consumables for the metal and material analysis (metallography and materialography) industries, based in Roskilde, Denmark.

We sat down (virtually) with Irma Rosli, R&D Engineer, from Akasel. Irma tells us about Akasel and the metallography industry, how she was able to continue her work using the nGauge AFM from home during the COVID-19 lockdown, and the value her team gets from AFM data, not just in R&D, but also quality assurance and even in marketing!

The interview has been edited for clarity and conciseness.

What does Akasel do?

Akasel develops consumables for metallography and materialography, which involves grinding and polishing to get a smooth surface finish that is suitable for characterization of the sample.

We develop products such as cut-off wheels, mounting resins, grinding discs and papers, diamond suspensions, polishing cloths, and lubricants that are used to prepare materials such as metals for metallography, and ceramics and glass in the optical industry for materialography.

Who are your customers and why do they perform metallography/materialography?

Our customers are from a broad range of industries, such as steel producers or companies in the automotive, aerospace or electronics industry. They use metallography to check the quality of their products or sometimes failure analysis. You can look at the structure of your material: you can etch it and then you can see the grains and the influence on the strength of the material: whether you have small grains or big grains.

What’s your role at Akasel as R&D Engineer?

I do a little bit of everything in R&D. My main task is to develop our suspensions as well as consumables such as polishing cloths, abrasive grinding papers, and diamond grinding discs. Questions such as what goes into that disc, what size of particles will produce what kind of scratch pattern, will it work with a lot of materials need to be considered and can be answered by doing many tests.

How do you use AFM?

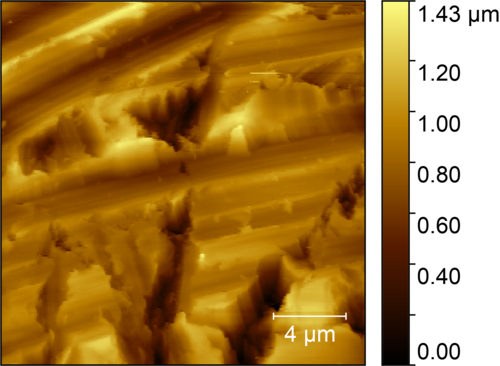

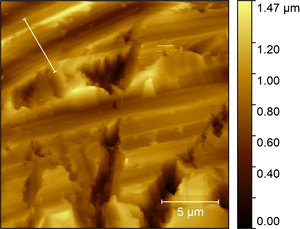

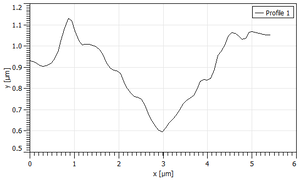

When developing a diamond suspension, the scratch patterns produced by the diamonds of different sizes are an important factor in evaluating the effectiveness of the suspension. It is also reflective of the lubrication system used in the suspension.

That’s why we use AFM: mainly to see scratch patterns and how deep these scratches go. In the final stage of polishing we would ideally get none, but there will always be some sort of scratch and we want to see how deep these scratches are. The lower the depth of a scratch the better. The data also gives us an idea about how our lubrication works.

What tools are typically used for metallography?

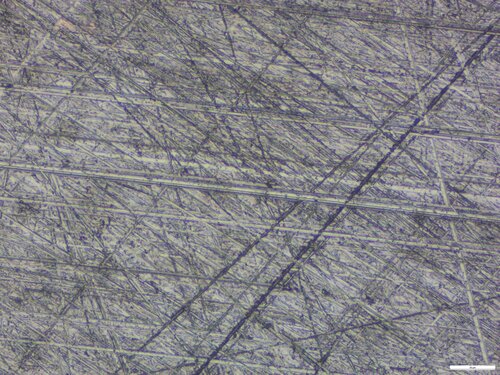

An optical microscope can give you an idea, but it can be deceiving sometimes because it is working with reflected light and you don’t know how deep the scratches go.

What value does AFM provide to Akasel?

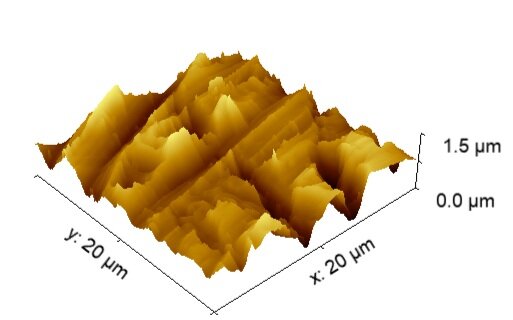

When you have an AFM you can render a 3D profile of your surface. I can get a numerical measurement of how deep the scratches go. I get numerical data instead of just an idea based on the picture.

The AFM data is useful for understanding the behaviour of our product. For example, we normally test a polishing cloth by polishing different sample materials. Then we look in the optical microscope, we see the scratch patterns and characterize the results.

Now with the AFM we can get measurements. Then we can further understand, for example, if we add more ingredient A or more ingredient B then we get these kinds of scratch depths. That is really helpful for us in formulating our suspensions.

Does the AFM data help in other ways?

We can also show our customers the numbers and the scratch patterns. In our product label we say that we use 3-micron diamonds, and not 4–5–micron diamonds. And it can also give us an indication about our diamond supplier if they are supplying us diamonds within the right limit.

It’s also good to show to our customers that we take our product development seriously and we go to this nanolevel to see the surface of our product. The 3D representation is also nice because you can see the surface instead of just a 2D picture. I can see all the bumps and scratches and I can put a number on how deep those scratches are.

How has the AFM data surprised you?

Now that I am working on actually developing the product, there is a lot more to just creating a diamond suspension, grinding and polishing a sample; there is also science behind it and then when you appreciate, when you learn how difficult it is getting data, extracting and processing it then you really get a different perspective and a different way of looking at things.

For example, when you look at a mirror you’d think oh it’s perfect and shiny but you’d never really think about the fact that the actual surface does have bumps and scratches. Yeah it’s the appreciation of little things (quite literally) around me that AFM has brought.

Tell me about what it’s been like to use the nGauge AFM at home while Denmark was locked down due to COVID-19.

In March, lockdown came and then I thought that the unit was the right size so that I could carry it home and do research at home on my dinner table. Due to the easy setup and the portability of the unit, I can simply pack it up again when I need to use the dinner table for something else. There is no need for a dedicated space for it, which is handy as I have a limited space in my flat. It was nice that the lockdown wasn’t putting a stop to this activity. I can analyze the images; we can understand the behaviour of our products and I can send the images to my colleague who can use them for marketing purposes. We don’t need to go to work to operate it, which is very convenient.